How does ultrasonic bonding work?

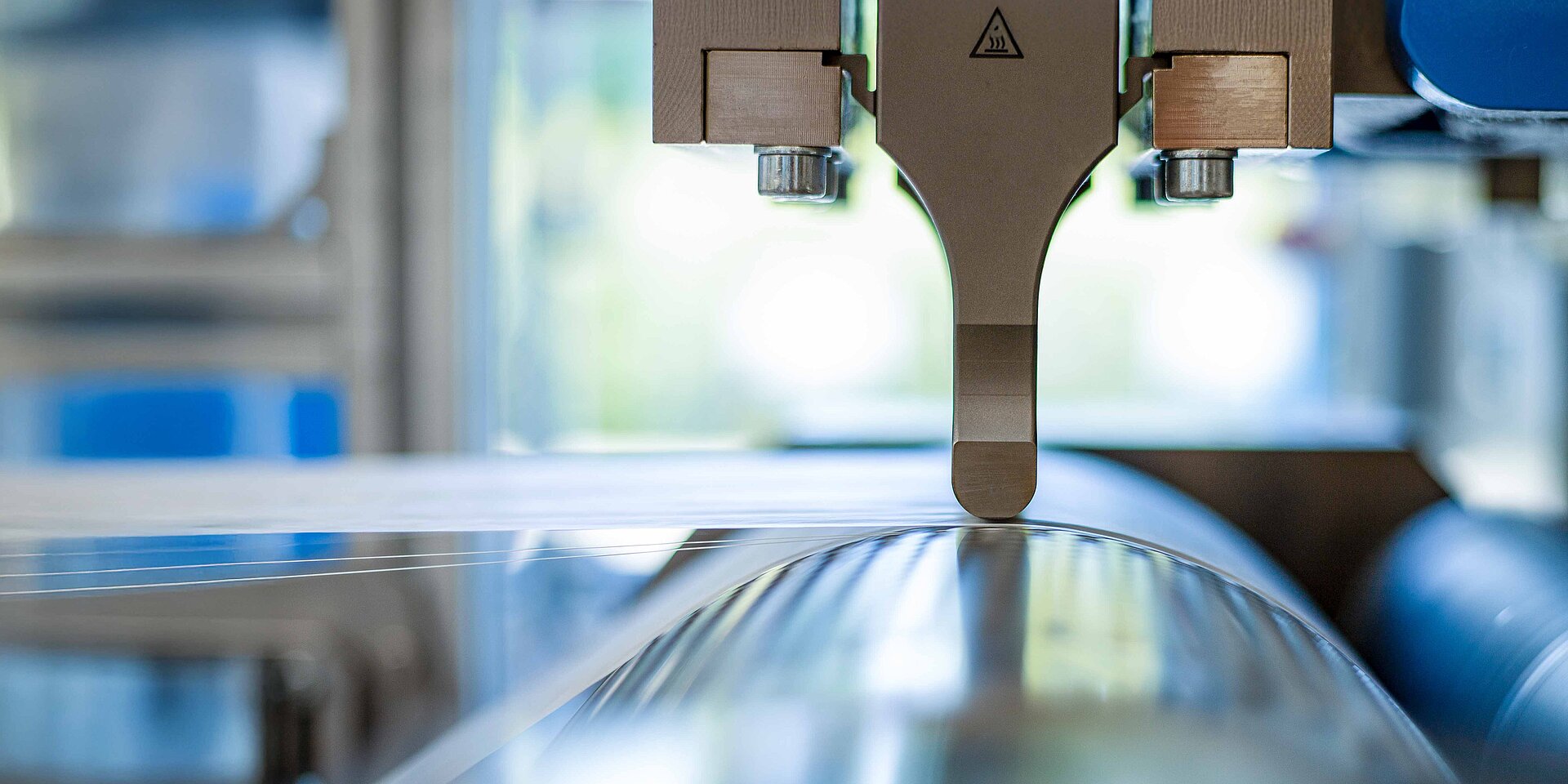

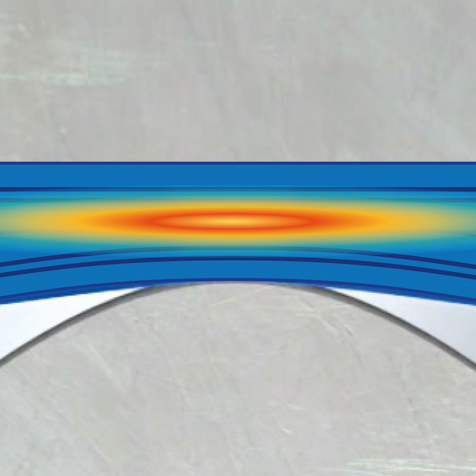

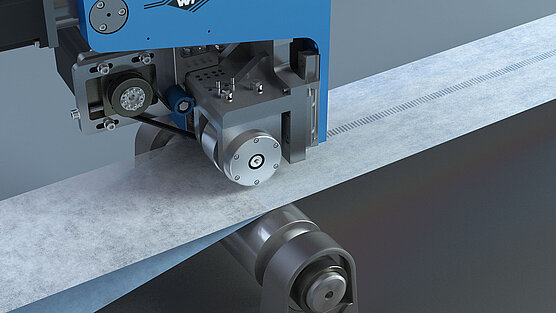

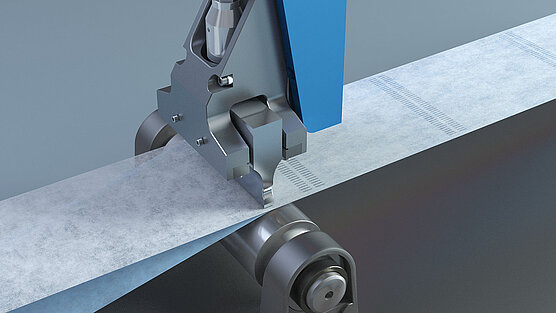

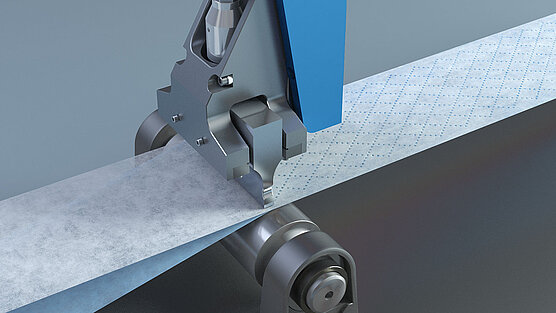

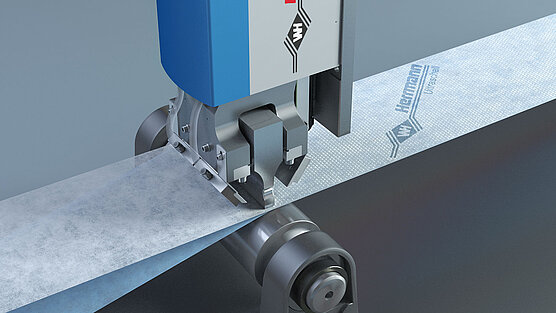

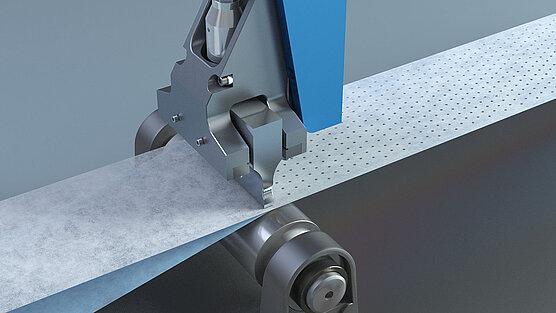

Ultrasonics are produced in the generator and transformed into mechanical vibrations in the converter. These are introduced into the material by sonotrodes. The standard frequencies here are between 20 and 35 kHz with an amplitude of 10 to 50 μm. The plastic portion of the material is stimulated, heats up and is melted. The actual bonding process is fast: Thanks to the use of rotating tools such as anvil drums, up to 800 m of nonwovens can be processed per minute. The anvil drum serves as an anvil and has an individual surface structure to focus the ultrasonic energy precisely.

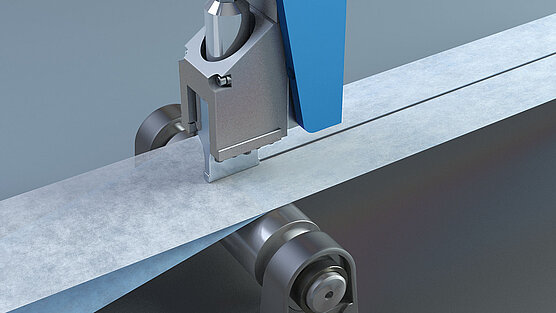

This allows exact weld, embossing or cutting results to be achieved. A constant distance between the material being processed and the tools is important for optimal results. This is guaranteed via Herrmann's MICROGAP control technology for ultrasonic bonding.

Nonwovens produced from fibers or continuous filaments can be processed by means of efficient ultrasonic welding, e.g. laminating, perforating, joining, embossing, cutting, or bonding.

There are two types of bonds that can be created with ultrasonics.

- A molecular bond can be achieved when similar materials (similar melting points and melt flow indexes) are bonded together. When using a mixture of materials comprised of different plastic fibers, their melting points should be as close together as possible to obtain optimum weld results.

- A mechanical bond is created when two dis-similar materials are processed. This is the case, for example, when nonwovens are processed with other materials such as woven fabrics, membranes, spunbonds, airlaids, films, and many more.

If you want to know whether we can make a bond your specific material combination, just get in touch and we'll run comprehensive tests in our ultrasonic laboratory.

Lower basis weight and thin materials less than 10 gsm are applicable to an ultrasonic bonding process.

Ultrasonics bonds materials together by applying ultrasonic sound energy to the materials, through a process that creates intermolecular friction. This results in strong, consistent and repeatable bond results. Ultrasonics is an effective and efficient solution for continuously bonding materials together, independent of the overall material thickness.

Contact us for further information and individual consulting on your application.

Continuous ultrasonic bonding enables very high processing speeds. Depending on materials and anvil pattern, production speeds of up to 800 m/min and even higher are achievable when materials, tooling, and system settings are optimally matched.

You can also find more information on this in our white paper “Your Guide for Maximum OEE In The Hygiene Industry”.

Ultrasonic bonding systems can be designed for various and expandable production widths beginning with just a few millimeters. Modular system architectures allow multiple ultrasonic units to be arranged side‑by‑side, enabling wide continuous bonding sections of greater than 3 meters.

Contact us for further information and individual consulting on your application.

Download Expert Resources

Learn more about the benefits of our ultrasonic bonding technology for your nonwovens application. Our downloads contain knowledge from more than 60 years of ultrasonics, providing valuable insights into advanced assembly techniques. By sharing our technical expertise, we foster a close partnership on equal terms, ensuring we can execute projects as quickly and successfully as possible.

Download our exclusive resources to unlock decades of innovation and stay ahead of the rapidly evolving hygiene products industry.

![[Translate to China - Englisch:] [Translate to China - Englisch:]](/fileadmin/_processed_/6/f/csm_TEi_7f015ae83d.jpg)