more OEE thanks to less maintenance and faster cuts.

longer service life thanks to individually tested sonotrodes.

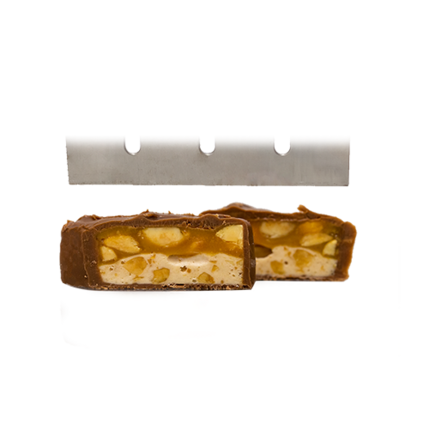

clean cuts for baked goods, confectionary, cheese and more.

Food Cutting 2.0: Precise. Robust. Food Certified.

High reject rates, long machine downtimes: Cutting sensitive food like cakes, confectionary, chocolate or cereal bars can be challenging. In this webinar, we show you the solution. With our ultrasonic cutting technology, you can reduce maintenance costs and improve your output permanently.

What you’ll learn:

✔ Introduction to ultrasonic cutting

✔ Key benefits of ultrasonic cutting for your application

✔ Success stories and best practices

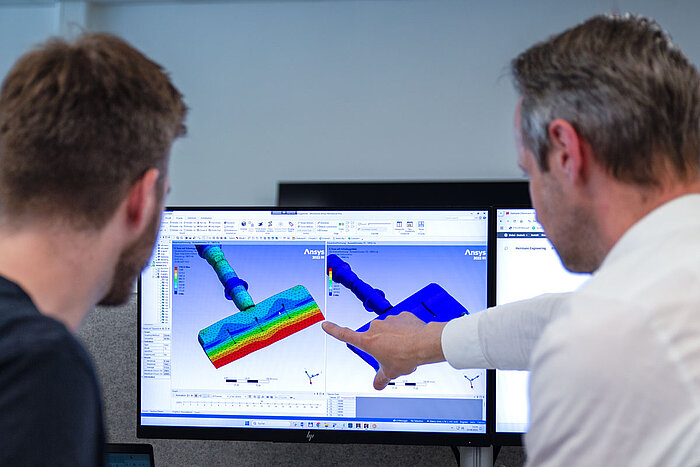

Benefit from our expert know-how

Discover Your Food Cutting Applications

Perfect cuts with perfect products

- Service life of up to 18 months and more

- Material certified for food applications

- Every tool individually tested

Increase your OEE and output with our durable sonotrodes. More than 60 years of ultrasonic experience allows us to offer you cutting tools that are especially durable and produce flawless cuts even when used continuously. Test our cutting tools in your plant!

FAQ – Ultrasonic Food Cutting

Ultrasonic food cutting is a precise cutting process that uses vibrations to slice through food products with minimal resistance. Electrical energy is converted into mechanical vibrations and transferred to the cutting blade, known as the sonotrode. Depending on the application, the sonotrode vibrates between 20,000 and 35,000 times per second in the direction of the cut.

This rapid motion reduces friction between the blade and the product, allowing for clean and consistent cuts even in soft, sticky, or multi-layered foods.

Ultrasonic cutting can be used for continuous and intermittent applications. The most common applications include:

- Slicing cheese, cakes, bread, and chocolate bars

- Portioning frozen and chilled foods

- Cutting sticky or delicate ingredients with precision

Learn more about the benefits of ultrasonic cutting for food applications in our free webinar.

Compared to conventional cutting methods like blades or wire cutters, ultrasonic food cutting offers clear advantages in quality, efficiency, and process stability.

- Precise cuts without pressure

The sonotrode vibrates up to 35,000 times per second. This enables precise material separation nearly without any pressure — preventing product deformation, smearing, or crushing, even with soft, layered, or sticky products like cakes, cheese, or bars.

- Clean surfaces, less waste

The high-frequency vibration greatly reduces friction and product sticking, resulting in clean cut surfaces and minimal residue. This improves hygiene and reduces product waste, saving costs and increasing output.

- Higher productivity, lower maintenance

Our durable ultrasonic systems enable faster cutting speeds and require less maintenance due to minimal tool wear. Even in continuous operation, our cutting sonotrodes can last up to 18 months and more. This leads to fewer unplanned stops and greater line efficiency.

- Energy-efficient operation

Ultrasonic cutting works without pre-cooling food and is largely temperature-independent, helping to reduce energy consumption and avoid production delays like empty oven runs due to maintenance.

Learn more about the benefits of ultrasonic food cutting in our free webinar.

Thanks to our experience in ultrasonics, we work with machine manufacturers all over the world. Our Trusted Advisors know exactly what steps are necessary to integrate our ultrasonic systems into large or small production lines. This way, we can ensure a fast and easy integration of our components.

Contact our team for more information.

As booster and sonotrode are made of metals, they are safe for CIP. The converter being the only part of the ultrasonic stack that is connected to electricity, this is critical for cleaning and CIP. Therefore, we offer converters with IP65 and IP67 in a protective tube system.

If you have any further questions, don't hesitate to contact our team. We're looking forward to your message!

Since ultrasonic cutting blades cut through food easily without pressure or resistance, the process is extremely fast. The cutting process can therefore be flexibly adjusted to the manufacturing speed without being a limiting factor in any way.

Learn more about the benefits of cutting food with ultrasonics in our free webinar.

Download More Expert Resources

Learn more about the benefits of our ultrasonic technology for your food applications. Our downloads contain the knowledge from over 60 years of ultrasonics, providing valuable insights. By sharing our technical knowledge with you, we ensure a close partnership on equal terms so that we can realize projects as quickly and successfully as possible.

Download our exclusive resources to unlock decades of innovation and stay ahead in the rapidly evolving food industry.

Partner with Us

Contact our PACKAGING Team to discover how our premium solutions can elevate the quality and effectiveness of your processes. We look forward to hearing from you!