Customer Story The Strainrite Companies

For over 40 years, The Strainrite Companies, a family-owned enterprise, have been a global leader in filtration across diverse industries like biopharmaceuticals, electronics, and beverages. Discover how they leveraged ultrasonic welding led to a 944% ROI in just 30 days, alongside a $120,000 increase in profits through optimized sonotrode design.

The challenges

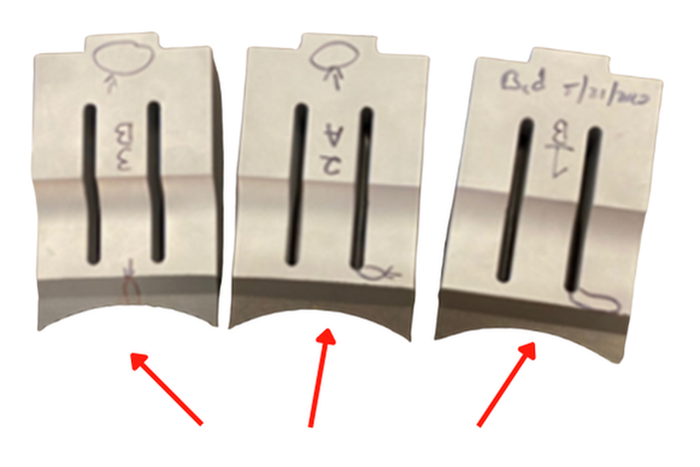

- Strainrite's production was hindered by faulty third-party sonotrodes – a critical tool for joining plastics in their filtration products – which frequently cracked due to poor design.

- This led to recurring production halts and significant financial losses, driven by costly replacements, reduced capacity, and increased downtime.

- The company urgently needed a reliable sonotrode solution to restore maximum productivity.

Our solution

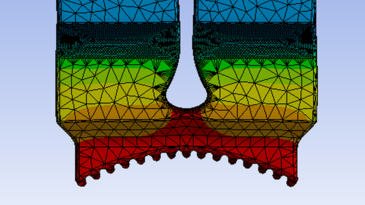

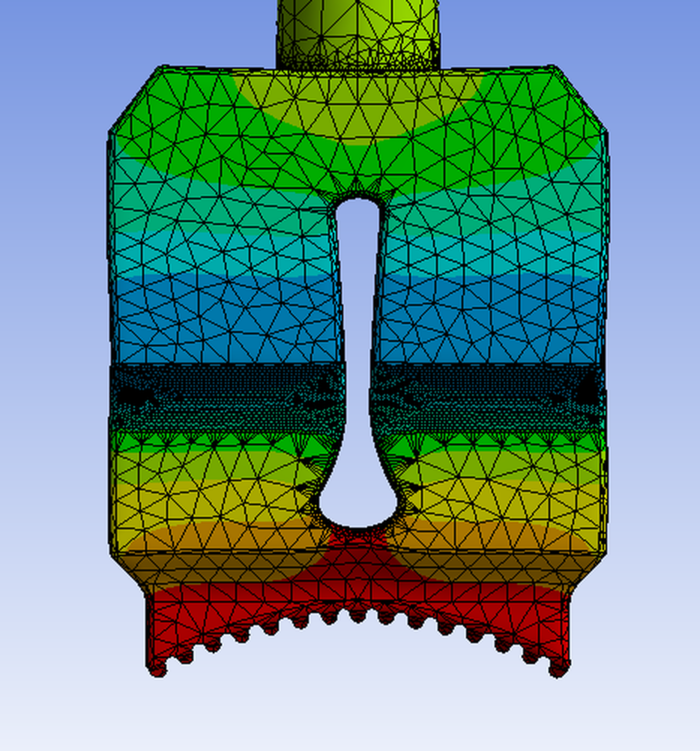

- Herrmann Ultrasonics introduced a novel tear-drop design for a new sonotrode.

- This innovative design provided a more uniform distribution of amplitude on the sonotrode's face, as confirmed by FEA analysis.

- The re-design ultimately led to improved performance characteristics of the sonotrode.

The new sonotrode operated 3 seconds faster per 15-second cycle than the previous tool. This resulted in a more than 20% production capacity increase. Because the production rate increased from 4 units per minute to 5 units per minute, this translated into a 25% output increase.

Customer benefits

Find out more in the complete customer story

Partner with Us

Contact our team to discover how our premium solutions can elevate the quality and effectiveness of your large-scale manufacturing. We look forward to hearing from you!