BONDING – MORE THAN MATERIALS

What makes Herrmann so special? What motivates us? We don't just want to bond materials, but most importantly the people behind them. From customers, partners and suppliers to employees and their families, all the way to our community, we want to bring together all those with whom we come into contact.

BONDING - MORE THAN MATERIALS is our central idea that unites us and drives us to perform at our best every day. It is the reason why our customers trust us. It is our WHY.

We are Herrmann

We work globally in the most dynamic, challenging and innovative markets. With our technological innovations, we create new trends and set new standards. Our employees are our most important asset – because they are doers, dynamic persons, turbo tinkerers, power professionals and horizon broadeners. They are energetic, flexible, independent and have the drive to deal with new situations and challenges in a professional and creative manner. They shape Herrmann.

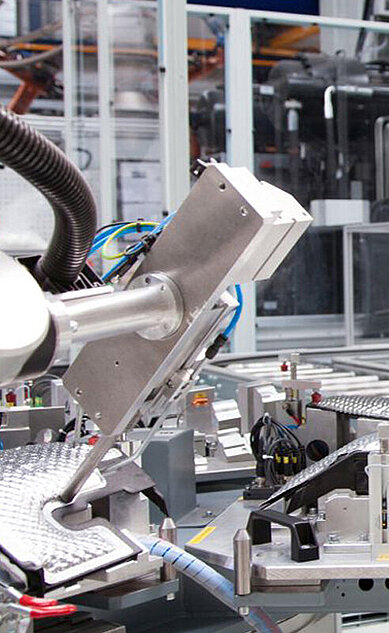

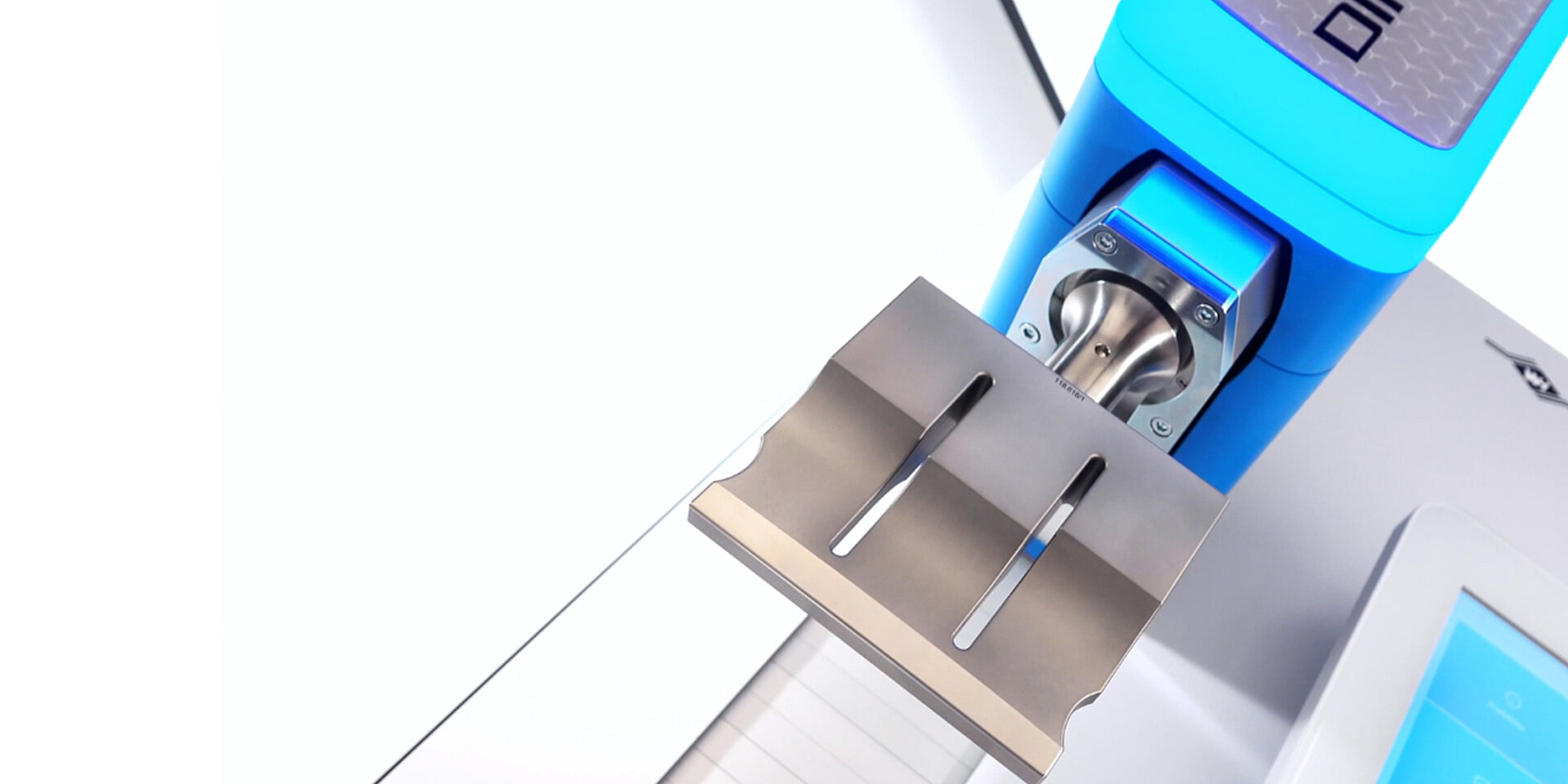

Plastics Packaging Nonwovens Metals

Ultrasonic welding means joining without adhesives, screws or heat from an outside source. During this process, material is strategically melted by means of ultrasonic vibrations so that a cohesive or form-fit joint is produced. As economic production method with short cycle times, ultrasonic welding ensures a large degree of process control and repeatable quality results.

![[Translate to China - Englisch:] [Translate to China - Englisch:]](/fileadmin/_processed_/2/c/csm_16x8_ELECTRONICS_Alarm_c28443bd50.jpg)