APPLICATION ENGINEERING

As a Trusted Advisor, we provide consulting services from the very beginning stages of your application. Whether it's material selection, component design, or process development, we know the right steps to take to develop a safe, sustainable, and economical welding process together. We rely on long-standing technology partnerships and the results from over our 40 technology centers. Only when your application is perfectly solved have we achieved our goal.

- Hand in Hand for the perfect solution

- Precise results thanks to the latest technology

- From sample part to manufacturing

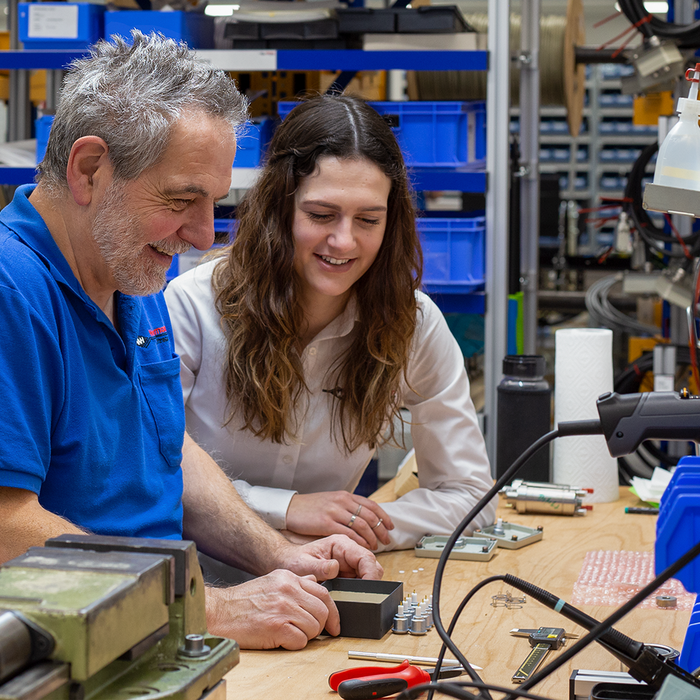

Hand in hand for the perfect solution

- Competent consulting in every phase of the project

- Experience from over 2.000 established applications per year

- Joint development of an individual solution

From the initial contact, we are at your side through every phase of the partnership. We know which steps are necessary to develop the ideal welding solution for you. We can master even complex customer requirements thanks to our experience of more than 2.000 solved applications per year.

With us as a Trusted Advisor, you receive maximum transparency in the partnership as well as a promising and efficient welding concept.

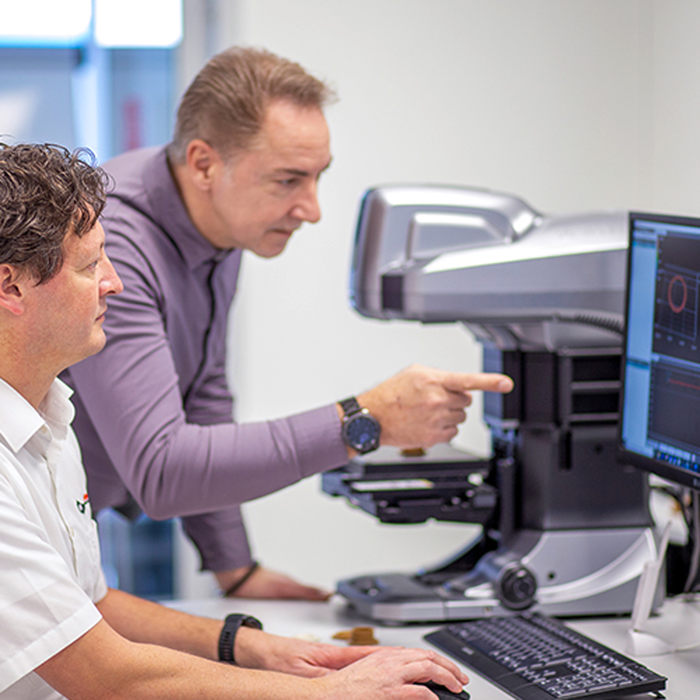

Precise results thanks to the latest technology

- More than 40 high-tech laboratories worldwide

- Optimized test rigs for meaningful results

- Detailed laboratory report for our customers

As our customer, more than 40 ultrasonic laboratories worldwide are availbale to you. With the help of our specialized measuring equipment, we carry out detailed tests on the effect of the welding tools, from tensile tests, leak tests, and burst pressure tests to thermography.

Our experts evaluate the results and provide them to you in a detailed laboratory report, including explanations.

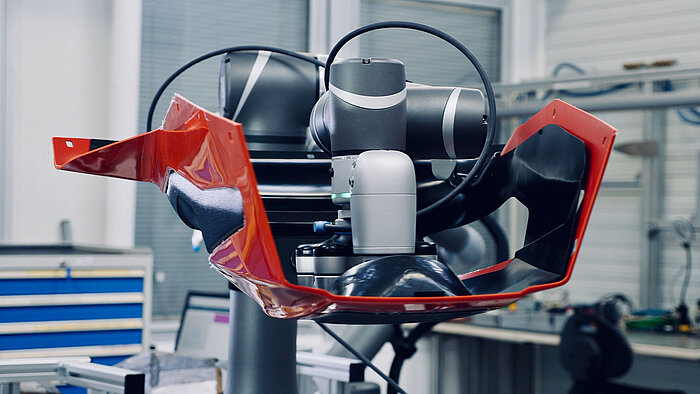

From sample part to manufacturing

- Production of sample parts

- Feasibility tests under near-production conditions

- Strict controls for an optimal welding solution

After successfully completing the tests, we start manufacturing the first sample parts. Under conditions as close to production as possible, these are subjected to stringent quality control and component validation.

For further function tests, the sample parts are handed over to you. We confidently reach our goal and start manufacturing only when the application meets your individual standard.